|

| Fig. 1: Basic Schematic of PWR Nuclear Power Plant. (Source: Wikimedia Commons) |

In the face of climate change and the rising levels of greenhouse gases, many people are turning to carbon-free energy sources to meet their energy needs. Some of the front runners in this field are renewable energy sources including solar and wind energy. However, these energy sources have a major limiting factor. They are not consistent. Solar panels only work when the sun is out. Windmills only produce electrical power when the wind is blowing. Unfortunately, the demand for electricity is typically higher when solar and wind are converting little to no electrical energy. The current approach to covering this energy gap is largely based on the burning of fossil fuels such as natural gas. However, if the world is serious about transitioning from carbon-based to carbon-free energy sources, then it is necessary to consider another energy source that is both consistent and emission-free, nuclear power.

Harnessing the energy of nuclear reactions, specificaly fission, is well understood and has been effectively demonstrated. Nuclear power is based on the natural splitting of heavy atoms, a process called fission, that occurs in certain elements known as fissile materials. A commonly used fissile material is Uranium. All of the fissile material, also known as nuclear fuel, is placed into a reactor core to contain all of the reactions that take place. The fission process releases huge amounts of energy, roughly 2.3 × 108 eV volts per fission. This is predominantly kinetic energy as the process ejects the newly split atoms and a very small particle called a neutron. These new atoms and neutrons go on to hit other atoms resulting in more fission reactions and increasingly larger amounts of heat. [1] This heat is then utilized, through varying designs, to convert this heat energy into electrical energy. The most common approach is to use the heat to produce steam and run a steam turbine to generate emissions-free electricity. [1,2]

The most commonly used nuclear power plant design to convert heat energy generated by nuclear fission reactions is the pressurized water reactor (PWR). A basic schematic for this design can be seen in Fig. 1. The PWR is a two-loop design, primary and secondary, that separates the steam plant from the reactor core. In the primary loop. the nuclear core is placed in a tank of pressurized water. The high pressure of the reactor prevents the water from boiling under the immense heat generated from the nuclear reactions. In the PWR design, the water acts both as a moderator and a coolant. As a moderator, the water slows down the neutrons to the thermal region to encourage further fissions. As a coolant, the water carries the heat away from the reactor core and is run through a heat exchanger to produce steam in the secondary loop. The secondary loop is the steam power plant where the steam produced is then used to run a turbine and convert heat energy into electrical energy. [1] The PWR design is a well-demonstrated, safe, and practical nuclear plant design.

Nuclear energy with all of its benefits does have some drawbacks. Namely, radioactive waste, high capital costs, and its inherent difficulty to follow the electrical demand when it increases rapidly. Radioactive waste is where a myriad of unstable atoms are leftover as a result of the nuclear fission reactions. These leftovers are constantly undergoing radioactive decays releasing energy and harmful radiation. [1] Regarding high capital costs, the major factors here are high-cost material requirements, increasingly stringent safety regulations, and project management missteps. Thus, nuclear power requires large initial investments resulting in long turnover times for profit. [3] The final discussed weakness of nuclear power is that nuclear plants have a difficult time responding to fluctuations in power demand.

Compared to fossil fuel energy conversion, nuclear power plants struggle to address the constantly changing electrical loads, a process known as load-following. To meet the fluctuating grid demand, conventional fossil-fuel-based power plants can increase and decrease their power output by burning more or less fuel. In nuclear plants, it is not desirable to ramp the plant's power output up and down for both efficiency and safety reasons. Considering efficiency, the optimal and most cost-effective operation mode of a reactor is at full power, 24/7. [4,5] Ramping the reactor down from full power results in lost energy that cannot be recovered. Ramping the reactor up to meet demand requires increased reactor core temperatures which require a slow and meticulous process. Also, increasing this temperature too quickly is not safe due to a phenomenon known as delayed neutrons. Because most conventional nuclear power plants utilizing the PWR design are directly coupled with the steam plants, this process of load following can be quite problematic as the demand of the grid is ever-changing. One way to address this issue is through the combination of nuclear power with a cheap and reliable energy storage solution.

|

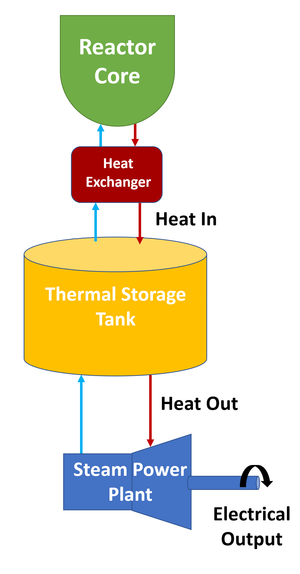

| Fig. 2: Energy vs. Time showing relationship between sensible and latent heat. (Source: S. Bernstel) |

To understand how energy storage can benefit nuclear power, a basic understanding of the topic relating to the grid is helpful. When electricity is generated, it must go somewhere. The electrical energy will either go to some load like a light bulb, be stored for later use, lost to the environment, or it may overload the grid and cause device and infrastructural failures. Obviously losing usable energy that costs money to convert is not ideal. Therefore, the solution is to store the energy in one form or another. There are many mechanisms to accomplish this. Electrical energy can be used to pump water behind a dam storing it in the potential energy of the water. A battery stores electrical energy by converting it into electrochemical energy. Most relevant to the scope of this work, heat can be stored as thermal energy in different heat transferring mediums.

When determining the appropriate energy storage mechanism for a specific application, the form of energy that is available is an important consideration. Storing the energy directly in the form available is typically better than transitioning from one form to another as there are losses associated with every conversion. For example, storing the electricity produced as thermal energy and then converting it again later to produce electricity has horrible round-trip efficiencies of around 40%. [5] Therefore, the least conversions in a power-producing facility the better, but costs of storage are also a factor in these decisions. Since heat is a natural product of nuclear reactions, storing the energy produced as thermal energy seems to be an efficient means of storage. Also, storing heat is a technologically simple task so it should be a relatively cheap and reliable energy storage adaptation for nuclear power. Thermal Energy Storage (TES) is discussed and compared to common storage techniques below.

In TES there are two storing mechanisms. The heat can either be stored as sensible or latent heat. Sensible heat is when the energy and temperature increase proportionately. Latent heat is energy that is stored as the material changes phase but the temperature remains constant. [2,4] These are visualized in Fig. 2. Utilizing latent heat energy storage can decrease the volume necessary to store equivalent thermal energy by up to a factor of 4. However, it can add to the complexity and cost of the system design. [4] The mechanism chosen determines the material used to store the energy. For sensible heat storage, common materials used are molten salts like sodium chloride/magnesium chloride eutectic. A common phase change material for TES would be Lithium Chloride which stores most of its energy in the heat of fusion, or the energy required to go from the solid to the liquid phase. [4] There are pros and cons to both, but the mechanism most commonly considered for nuclear power application is sensible heat storage in molten salts. [2,4,5] To understand this decision, other factors such as cost and capacity are considered.

When determining what energy storage mechanism works best for a specific application, it is important to consider the energy and power capacities of the storage mechanism, the costs associated, and the size of the plant. Energy capacity describes the amount of energy technology can store and power capacity is the rate at which this energy can be discharged. Each of these has unique costs associated with the technology being referenced. The necessary size of a plant can be determined by the energy density providing an energy per unit volume measure of a storage mechanism. [2] All are important factors in energy storage applications. Two of the most common energy storage technologies currently in use includes pumped storage hydropower (PSH) and lithium-ion batteries so they will make good comparisons for TES. Here are the numbers. PSH has an energy capacity of 500-8000 MWh at a capital cost of 5-100 $/kWh. The power capacity of PSH is between 100-5000 MW costing around 2000-4000 $/kW. The energy density of the power plant is very low coming in at 0.5-1.5 kWh m-3 meaning large plants would be necessary to store substantial amounts of energy. PSH has an estimated 6-10 hours of discharge time depending on the amount of water available. [2] Lithium-ion energy storage has an energy capacity of around 0.25-25 MWh at a cost of 600-2500 $/kWh. In power capacity, lithium-ion storage has is rated between 0.005-50 kW with a price tag of 1200-4000 $/kW. The energy density of Lithium-ion batteries is quite high at 200-500 kWh m-3. The discharge time associated with Lithium-Ion batteries is between minutes and hours. [2]

|

||||||||||||||||||||||||||||

| Table 1: A comparison of the most common energy storage technologies and Molten Salt Thermal Energy Storage (TES). [2] |

Using molten salts as the energy storage medium, TES is very competitive to these common energy storage mechanisms. A brief summary of this comparison can be seen in Table 1 above. In energy capacity, molten-salt TES is shown to have 350 MWh of capacity at a cost of 5-10 $/kWh. The energy density of the technology is comparable to Lithium-Ion at 170-420 kWh m-3. Unique to TES, the power capacity is not dependent on the storage mechanism. Instead, the power capacity of TES depends on the power plant it supplies heat to. Meaning there is not a specific power capacity associated with the storage mechanism. That being said, the power capacity cost is predominantly dependent on the cost of the TES tank and storage medium, so a power capacity cost is provided at around 400-700 $/kW. [2] By far the cheapest cost between the storage techniques for power capacity providing a cheaper means to meet rapid surges in demand. With regard to discharge time, this is also dependent on many factors and not easily reported in a general sense. To provide some perspective on the matter, molten salt TES has been demonstrated in Spain in conjunction with concentrated solar energy to produce power during the evenings. The plant was able to provide the heat necessary for 7 hours of power production and plans are already in place to scale this up to a 16-hour full-capacity plant. [2] In contrast to PSH, TES is not dependent on its environment and can be supplied heat continuously when coupled with nuclear power. It also has a substantially larger energy density than PSH requiring smaller facilities to store larger amounts of energy. From this reporting, it can also be seen that TES demonstrates competitive energy capacity and has a power capacity that is not limited by the storage technology but by the power plant-associated. It is also found that TES is a very cheap energy storage mechanism when looking at the costs associated with energy capacity and especially in power capacity. TES also has substantial discharge time capabilities depending on the size of the plant, the storage, and the heat source used. When a continuous carbon-free heat source like nuclear power is implemented, it can be concluded that TES is a cheap and effective means of storing energy for power production.

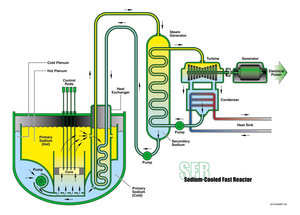

One of the more popular proposed Nuclear-TES design configurations is implementing TES as an intermediate loop between the nuclear core and the steam power plant. [2] See Fig. 3 for a simplified schematic of this configuration. This configuration addresses several of the problems associated with the current nuclear power technology and provides pathways to making nuclear power more affordable. Another appealing factor of this design is it allows for easy integration with other carbon-free heat sources such as concentrated solar power. [4]

The TES integration concept mentioned above addresses several of the issues inherent to nuclear power. To start, TES allows the nuclear reactors to operate at full power around the clock. This is because, with TES integration, the heat from the reactor is decoupled from the power output of the steam power plant. Instead, the full-power operating reactor consistently supplies large amounts of heat energy to be stored in the intermediate TES tanks. [4,5] To help quantify this, a study published in the Energy Policy Journal stated that the optimal TES addition alone can store 8-12 hours of thermal energy required for 150% reactor-rated power output. Furthermore, when supplemented by the constant reactor operations, this 150% ramped power output can be extended. This study suggests that a 100 MWe rated reactor, when coupled with a fully charged TES tank and a 150 MWe rated power plant, could produce maximum output for 16 hours without ever once changing the thermal output of the reactor. [5] Conversely, when electrical demand is low, larger amounts of the reactor's thermal energy can be stored in the TES system to use at a later time when electrical energy demand and profits are higher. These are the extremes, but the thermal energy stored in a TES-nuclear combined cycle can also be intermittently tapped to produce steam and electricity at varying outputs as the demand requires. This means that combining TES with nuclear power also enables the nuclear plant to load-follow without straining the reactor and avoiding the safety concerns associated with changing the reactor's output. A major drawback to current PWR nuclear power plant applications. [2,4]

|

| Fig. 3: General Schematic showing the three isolated sections of TES-Nuclear combined system. (Source: S. Bernstel) |

Combining TES with nuclear power also has implications on the cost and profitability of nuclear plants. As noted above, nuclear power plants have large costs associated with their construction and maintenance. In a conventional power plant, the only product the plant provides is baseline electrical power. With the Nuclear-TES combined systems' load-following capability, these power plants are able to provide both baselines and ramped electrical power. [2,4,5] In Nuclear-TES, it can also provide valuable heat and steam as a product to both the public and private market. [2,4] This could include chemical plants, steel plants, hydrogen production facilities, public utility providers, and many other entities. The main idea here is that TES will increase the profitability and return on investment of nuclear power making it a more affordable and maybe even profitable energy solution.

This idea was modeled in a 2020 study conducted by researchers in collaboration with Oak Ridge National Laboratory. A model was made to estimate the profitability of two versions of the TES-Nuclear combined system in all of the grid markets across the United States for varying electricity production scenarios in conjunction with renewable sources. The model evaluated the TES system in conjunction with a 3500 MWt reactor operating at 33% efficiency. The study considered two TES designs. One where the TES was an add-on to an existing plant and the other where the TES was fully integrated between the reactor core and the steam plant. The study concluded that TES-nuclear integrated systems show good promise of increasing the profitability of nuclear power plants, particularly the fully integrated design. The model showed that all but 6 of 28 simulations for the fully integrated plant showed increased revenue compared to a conventional plant over a 20-year period. Some scenarios even show increases in revenue upwards of 450 million dollars. [6] Despite the positive results of the model regarding the TES-Nuclear combined system, this model depends heavily on outside factors such as weather conditions over a 20-year period and the energy market and ancillary market available for the grid service modeled. These variables are constantly changing and very difficult to predict.

The Nuclear-TES combined system does have some drawbacks. For one, introducing intermediate steps and more heat exchangers to a system inherently introduces efficiency losses to the the system. Secondly, the heat storage medium for the TES considered in most combined systems is molten salts. This is good because it is a well-established TES technology using stable and environmentally friendly materials. [2] However, molten salt energy storage is typically conducted in the liquid phase between the mediums melting and boiling point. These temperatures range, depending on the salt selected, but tend to be much hotter than PWR output temperatures that tend to be under 300°C. [5] For example, common salts used for energy storage such as Sodium Nitrate or Potassium Nitrate have melting points between 300-500°C. However, the salt is usually stored well above these melting temperatures to avoid complications with freezing the salt for storage, pumping issues, and reactor cooling safety concerns. [7] These high temperatures introduce some issues as high-temperature salts can be very corrosive. This, however, can be mitigated by salt and material selections. Another factor is that due to the high-temperature storage of these molten salts, the pursuit of more advanced higher temperature reactors, such as sodium-cooled fast reactors have been proposed. [4,5] This introduces more difficulty into the adoption of the Nuclear-TES combined system because advanced reactors are expensive, not well demonstrated on the commercial scale, and often introduce other risks such as proliferation.

Despite some of these concerns Nuclear-TES has shown evidence of being a viable and promising step towards more reliable carbon-free energy that easily couples with both renewable solar and nuclear power. Because of this, the technology has captured the imagination of some real investors and is currently being evaluated at the proof-of-concept level in coordination with the Department of Energy (DOE).

One of the leading groups implementing the Nuclear-TES combined plant is Bill Gates's Terra Power with their proposed Natrium system. Terra Power is working with Energy Pacificorp to build a demonstration plant on the site of a decommissioning coal-steam power plant in Kemmerer, Wyoming. It is being built in conjunction with the DOE's Advanced Reactor Demonstration Program which has provided substantial funds to the project. We can expect the Natrium system demonstration to have the main three components of a Nuclear-TES plant as seen in Fig. 2 including the reactor, the TES tanks, and the steam power plant.

|

| Fig. 4: General schematic of sodium-cooled fast reactor. This reactor design inspired the PRISM reactor used in Natrium. (Source: Wikimedia Commons) |

The Natrium System is trying to reach higher temperatures for salt storage by implementing an advanced high-temperature reactor. Developed by GE Hitachi, Natrium intends to use a 345 MWe sodium-cooled fast reactor called Power Reactor Innovative Small Module, or PRISM. [8,9] A general schematic of a sodium-cooled fast reactor is provided in Fig. 4 and a rendering of the PRISM reactor and containment is seen in Fig. 5. PRISM is based on the technology of the experimental breeder reactor, (EBR-II) developed and operated at Oak Ridge National Lab in the 1960s. Similar to the EBR-II, PRISM intends to implement integral fast reactor capabilities in order to reduce the conversion ratio of the reactor below 1 if desired. [8] This means that, despite the reactor's natural tendency to produce transuranics as reactions take place, certain mechanisms can be activated to allow the reactor the capability to burn entirely through the transuranic fission products generated during reactor operation. The idea is to reduce waste as well as reduce weapons proliferation and terrorism concerns. The PRISM reactor design is fueled by high assay low-enriched uranium (19.75% enriched) providing between 800 and 1000 Megawatts of constant thermal power. [9] This is also an area of concern with the reactor design as most conventional reactors avoid going above 6% enrichment due to the concern of nuclear runaway accidents. This concern is usually addressed with the passive-fail safe argument that most advanced reactor designs boast. PRISM claims to offer a temperature-based passive fail-safe, suggesting that in the case of nuclear runaway or coolant circulation loss, the increased temperature of the core would result in increased neutron absorption. This passive process would act as a negative feedback loop and theoretically stop further reactions from occurring. [7,8] Pardon the pun, but the apparent benefits of advanced reactors must always be taken with a grain of salt. They often promise much and deliver little. Specifically, sodium-cooled reactors have proven to be quite difficult and expensive to operate having been described by the Father of the Nuclear Navy, Hyman Rickover, as being expensive to build, complex to operate, susceptible to prolonged shutdown as a result of even minor malfunctions, and difficult and time-consuming to repair. [10]

A particularly problematic component of this advanced reactor design is the coolant. As the name suggests, the coolant in this reactor is a sodium metal instead of water commonly used in the PWR design. This is what makes PRISM a fast reactor. In short, molten sodium metal absorbs very little energy from incident neutrons preventing them from thermalizing and maintaining very high speeds until they induce another fission or absorption to produce transuranic materials. [8] The latter effect is a key feature of sodium-cooled reactors that enables them to breed weapons-grade plutonium. One reason for the interest in this reactor design is the much higher boiling temperature of liquid sodium at atmospheric conditions when compared to water. Sodium metal boils at 882°C versus water at 100°C. [8] This feature allows the reactor operating temperature to be higher while the pressure of the reactor containment can be near-atmospheric without the conventional concern of boiling the coolant. The higher temperature operation also allows for more compatible and more valuable thermal storage in the molten salt TES tank. The lower pressure reduces the costs associated with the reactor containment. However, a major drawback of this coolant is its flammability when exposed to air or water. If there are any leaks in the reactor containment that introduce air to the extremely hot liquid sodium, it could result in catastrophic fires or explosions releasing harmful materials and high levels of radiation.

|

| Fig. 5: Rendering of the GE Hitcahi PRISM reactor. (Source: Wikimedia Commons) |

The other two components of the Natrium system are the TES and the steam power plant. The TES used in the Natrium system is an intermediate loop, nitrate molten salt TES tank. [9] It serves as the storage and discharge mechanism between the reactor and the steam power plant. An important feature of this intermediate loop is that it allows for 24/7 maximum-power reactor operation. The heat is continuously stored in the molten salt TES and the heat is discharged on command either as a heat product or electricity. This decoupled system also enables the plant the crucial capability to load-follow with ranging outputs between 100 and 500 MWe. The Natrium demonstration plant should be able to support a maximum load (500 MWe) for up to 5.5 hours. [9] The final advantage of the TES used is that it can easily be coupled to a large concentrated solar field alongside the nuclear plant enabling further storage and value to the plant. The steam plant is intentionally left as a simple steam power plant. Keeping this part of the design simple is a key feature because it allows for easy integration with old steam systems, such as coal power plants, that are currently being decommissioned across the world. This sort of integration is another point that Terra Power hopes to demonstrate with this plant as well.

Terra power is working on building a demonstration Natrium power plant in Wyoming using $2 billion in funding received from the Department of Energy (DOE). [9,11] This location was selected in part due to its proximity to a coal power plant that is scheduled to retire in 2025. [9] The deadline set by the DOE is to have the plant up and running by 2028. However, considering that this is a first-of-a-kind implementation of an advanced reactor being built for commercial purposes and large-scale demonstration, it can be expected to face considerable construction and technology issues, bureaucratic friction, and substantial regulatory scrutiny. [9,11] Nevertheless, if Natrium is successful, it will be the first TES-Nuclear combined system in the world and a major achievement for the nuclear community as a whole.

TES is a cheap and effective energy storage method that couples well with nuclear power. When combined, TES allows the reactor to operate at max power around the clock, it enables the power plant to load follow without putting added strain on the reactor, it can easily be integrated with current renewable energy sources, and it provides another source of revenue to the power plant by selling the heat for various services alongside the electricity produced. All of these benefits increase the apparent profitability of nuclear plants, compared to the conventional designs, and bring nuclear power back to the table as a more appealing option in the energy sector. Companies, like Terra Power, see these benefits and are placing their bets on the combined design by building a demonstration plant in Wyoming. However, they are also embracing a more advanced and less developed sodium-cooled fast reactor design and will certainly face many challenges because of this. This, however, should not turn people away from the prospect of TES-Nuclear combined applications. The focus should be on finding a safe and reliable way to combine TES with nuclear energy as a promising and carbon-free approach to meeting modern-day energy needs.

© Sean Bernstel. The author warrants that the work is the author's own and that Stanford University provided no input other than typesetting and referencing guidelines. The author grants permission to copy, distribute and display this work in unaltered form, with attribution to the author, for noncommercial purposes only. All other rights, including commercial rights, are reserved to the author.

[1] M. Joyce, Nuclear Engineering: A Conceptual Introduction to Nuclear Power (Butterworth-Heinemann, 2017).

[2] J. Coleman et al., "An Evaluation of Energy Storage Options for Nuclear Power," Idaho National Laboratory, INL/EXT-17-42420, June 2017.

[3] P. Eash-Gates et al., "Sources of Cost Overrun in Nuclear Power Plant Construction Call for a New Approach to Engineering Design," Joule 4, 2348 (2020).

[4] S. Alameri and J. C. King, "A Coupled Nuclear Reactor Thermal Energy Storage System for Enhanced Load Following Operations," Colorado School of Mines, November 2013.

[5] P. Denholm et al., "Decarbonizing the Electric Sector: Combining Renewable and Nuclear Energy Using Thermal Storage," Energy Policy 44, 301 (2012).

[6] K. Borowiec et al., "Increasing Revenue of Nuclear Power Plants with Thermal Storage," J. Energy Resour. ASME 142, 1 (2019).

[7] J. Dodaro, "Molten Salt Storage," Physics 241, Stanford University, Winter 2015.

[8] J. M. Hylko, "PRISM: A Promising Near-Term Reactor Option," POWER Magazine, 1 Aug 11.

[9] S. Patel, "Coal Plant Site Unveiled for 500-MW Natrium Advanced Nuclear Pilot," Power Magazine, 17 Nov 21.

[10] T. Rockwell, The Rickover Effect: How One Man Made a Difference (Naval Institute Press, 1992).

[11] E. Negin, "So-Called Next Generation Nuclear Power Plants Are Being Oversold," Scientific American, 23 Jul 21.