|

(Click for Oceaneering ROVs Page) |

Heavy Weather Deployment |

|

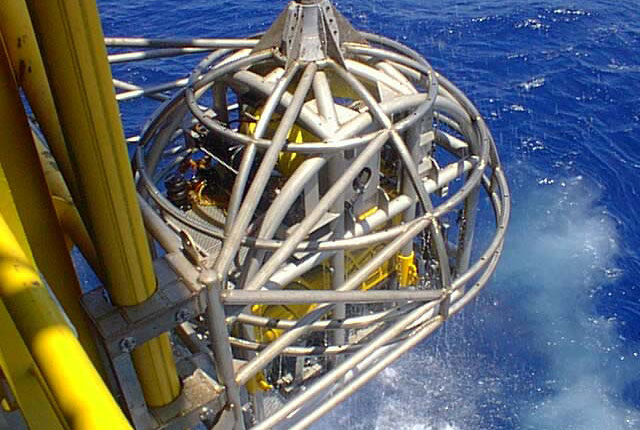

The following section is meant to help to educate prospective clients on the purpose, variations, and factors that effect the design, installation, and operation of a heavy weather ROV launching system. Oceaneering's experience with the use of heavy weather deployment systems began in the 1960's when the concept was first applied to manned diving bells. The purpose then as well as now was to increase the weather window for deployment. This reduces the "Waiting On Weather" time. A great deal of experience was gained from these early experiences and applied to our ROV operations in the early 1980's. In past years, Oceaneering would typically install approximately two cursor systems per year on drilling rigs and dive support vessels. Since that time, a number of variations and enhancements have been developed. These variations and enhancements allow Oceaneering to suit any vessel from a dive support vessel to an ultra-deepwater drillship or rig. In the past two years, Oceaneering has installed 20 heavy weather launch systems. This is due to the increase of the number of vessels moving into deeper water in harsh weather areas, higher cost of vessel time and the increased dependence on the ROV during subsea operations. This dependence on the ROV especially in deepwater and the cost associated with vessel downtime, has made the additional cost of the cursor system seem more attractive (usually equal to 24 hours of rig time). Heavy Weather Launch SystemsThe main purpose of the heavy weather launch system is to stabilize and centralize the ROV and cage with a device that restricts horizontal movement and uses its weight to speed the transition time through the splash zone. The air-sea interface presents the greatest risk of damage to the ROV, cage, and potentially the vessel. Large waves and high winds can cause the ROV and cage to swing wildly, potentially hitting vessel structure. As the vehicle is raised, this motion is amplified many times similar to shortening the string on a pendulum. The greatly amplified swinging can make it difficult if not impossible to recover the ROV. This can cause excessive side loading on the a-frame, which will cause it to fail. Oceaneering designs a typical rough weather launch system to operate in a 10 year Gulf of Mexico storm. This equates to approximately a sea state 6, which is an 18-22 ft significant wave height. Another hazard on some vessels is the close proximity of the ROV to thrusters. Many of the new deepwater vessels are dynamically positioned using thrusters rather than held in place by anchored. Due to the size and power of these thrusters, ROV systems can easily be destroyed. Heavy weather launch systems move the pivot point for the umbilical from the a-frame to the bottom of the vessel. This minimizes the risk of the ROV and cage being pulled into a thruster, destroying the ROV and cage and causing major damage to the thruster. The single most disruptive failure that can occur to an ROV system is the failure of the umbilical due to the long period of down time to repair the failure, and the time it takes to transport and change out a new deepwater umbilical offshore. If heavy wave action or high currents should drive or push the cage onto its side, the umbilical termination on the top of the cage can be bent at a severe angle resulting in this type of failure. For this reason, another important purpose of the heavy weather launch system is to maintain the vertical orientation of the ROV cage. Design DescriptionOceaneering currently has several different types of heavy weather launch systems, but they all have one piece in common. This piece is called a cursor. The cursor is the essential piece of equipment that allows the heavy weather launch system to safely deploy and recover the ROV. The cursors are fabricated from stainless steel pipe with very few moving parts and almost no maintenance. It is in the shape of an upside down bowl that encompasses the top half of the ROV and cage. The cursor travels a constrained path down the side of the vessel on guide wires or rails. The cursor travels with the ROV and cage until the cursor stops at the point where the wires or rails are terminated subsea. The wires or rails are terminated at the deepest possible level on the vessel structure. The cursor is also perforated with 1" holes to allow it to flood as fast as the winch can lower it. This combined with the weight of the cursor helps transit the cage through the waves as quickly as possible to reduce "hesitation." ("Hesitation" is the second or two that a standard system seems to float at the interface while the ROV and cage become flooded and begin to sink.) The Magnum and Millennium cages are designed to be extremely negative and possess as great of a weight to drag ratio as possible. A low center of gravity is achieved by adding approximately 1 Ω tons of lead to the bottom members of the cage. These characteristics allow the cage & ROV to contribute to the cursor performance. Additionally, once the cage and ROV have left the cursor and transited down to the work site, the low center of gravity will help it to be minimally affected by upper and intermediate currents. Design ConsiderationsA number of factors need to be considered when selecting a configuration best suited for a specific application. Environmental conditions, vessel type, and the vessel limitations should serve as the base line for the selection. Space limitations and access to attachment points on the vessel lower hull or pontoons must be considered as well. These considerations result in the selection of one of the following configurations. Guide Wire Cursor Deployment Systems |

|

The most commonly used cursor system in Oceaneering's fleet uses guide wires. This method for constraining the cursor's path has been used many times since 1984 with great success. The guide wire system is typically used on drilling rigs, tension leg platforms, and other similar installations. This method is useful when some horizontal movement is acceptable and there is no structure present to attach rails too. Cursor guide wire lengths range from 140 ft -150 ft. A pair of 2 in parallel wires are strung from the fixed a-frame on deck to lower cursor arms, which are either bolted or welded to the pontoon. A specially designed and tested breakaway joint connects the wires to the lower cursor arms. This breakaway joint prevents damage to the a-frame, vessel, and most importantly personnel if a wire becomes overloaded. A method of tensioning the wires is also needed. This is accomplished using turnbuckles to connect the wire to the a-frame. The guide wire system enables Oceaneering to offer a heavy weather launch system with excellent operational characteristics for semi-submersible drilling rigs, and other similar vessels. Rail Cursor Deployment Systems |

|

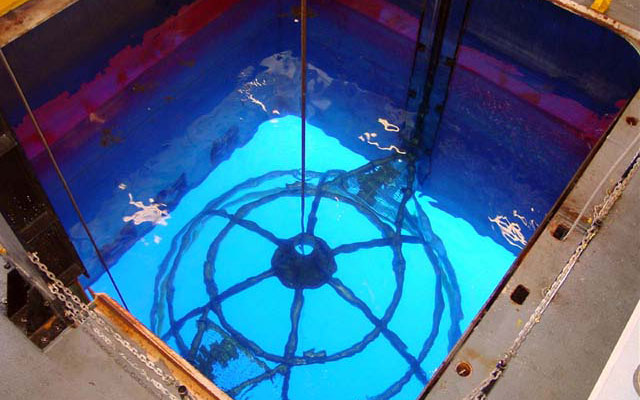

Oceaneering employs a guide rail to constrain the cursor's path. This method is best suited to drill ships, dive support vessels, and other vessels where no horizontal movement is desirable and on vessels that launch through a moonpool. Typical rail lengths are 70 ft -80 ft in length. The rails are attached to the vessel at several points between the ROV deck and the vessel keel. Rail systems can be used in an over the side launch with an a-frame, or through a moonpool with a fixed a-frame. Both of these systems provide excellent heavy weather launch performance. Moonpool Systems |

|

Oceaneering's Intervention class vessels are equipped with dedicated ROV moonpools which allow operations in extreme sea conditions not normally possible in other ROV installations. SummaryOceaneering currently has 20 new-generation cursor systems installed on vessels worldwide. Some of these systems are installed on older vessels during refit, but the majority of these systems are installed on new ultra-deepwater drilling rigs and drill ships. These vessels are designed to work in 10,000 fsw and stay operational in rough weather. Our approach is to be involved with the customer from an early stage in the design of the vessel to facilitate and optimize the design, installation, and operation of it's ROV system. The combination of the vessel's capabilities and those of the heavy weather launch system provides our clients with more operational time and less "waiting on weather" down time with an ROV system that has typically divable beyond the point where the vessel ceases its operations due to weather. |