|

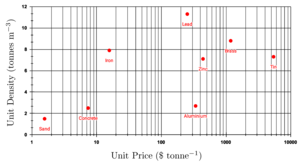

| Fig. 1: A comparison of unit price to unit density for a variety of materials. [1] (Image Source: S. Blinkman) |

In the lifecycle of energy, where energy generation and consumption power the modern world, energy storage is the crucial link. There is an ongoing imperative for efficient energy storage systems in addressing the intermittency of renewable energy generation. Currently, there are many energy storage methods that can be generalized into a few forms. These forms include mechanical, electrochemical, chemical, electrical, and thermal energy storage. Table 1 below gives a few common energy storage systems of each form.

Under the umbrella of mechanical energy storage systems there are kinetic energy storage (KES) and gravitational potential energy storage (GES). Fundamentally, GES displaces heavy objects vertically increasing potential energy when raised and releasing stored energy U (measured in Joules) when lowered, according to

| U | = | n Σ i=1 |

mi g hi |

where mi is the mass of the ith object in kg, hi is its height in m, and g = 9.81 m/s2 is the acceleration due to gravity.

As of 2022, 90.3% of the world energy storage capacity is pumped hydro energy storage (PHES). [1] Although effective, a primary concern of PHES is the geographical constraint of water and longer term scalability. In this report, I will introduce solid gravity energy storage as an emerging alternative GES and explore a few primary systems.

|

|||||||||||||||||||||||||

| Table 1: Examples of systems within general forms of energy storage systems. [1] |

SGES utilizes the same principles as all gravity energy storage systems. The distinction being solid GES uses solid materials, such as concrete. Large blocks of these heavy materials are raised and dropped vertically, storing, and releasing the gravitational potential energy. In comparison to PHES, SGES achieves better geographical adaptability, scalability, energy density and cycle efficiency. [1] The material of the solid object is important to the capacity, efficiency, and cost of SGES systems as materials have differing densities and prices. Fig. 1 displays the relationship between unit price and unit density for a variety of materials. The relationship is generally linearly increasing; however, some materials appear better than others. For example, iron and lead have a better density to price ratio than aluminum. Additionally, material scarcity is an important consideration. These decisions all have an impact in the efficiency, scalability, and geographical adaptability of SGES systems.

In the next sections, I will introduce three primary SGES system. For each system, I will cover typical capacity, efficiency, service life cycles of each system.

|

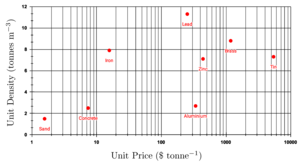

| Fig. 2: A diagram of the essential components of a tower solid gravity energy storage system (Image source: S. Blinkman). |

The T-SGES system, as depicted in Fig. 2, uses electromechanical motor-generation units to lift and stack blocks into a tower. As more energy is stored, the control center stack blocks onto higher blocks. When energy is need, the crane system lowers the blocks toward the base of the tower and the motor-generation unit recaptures the energy. The T-SGES is intricately driven by software incorporating many motor-generation units, pulleys, and blocks to allow for driving many operations simultaneously.

The total energy capacity for a T-SGES system is calculated by using the equation [1]

| ET | = | ηT × | n Σ i=1 |

mi g hi |

The cycle efficiency of the tower, ηT, is essential to the total energy capacity. For towers, this value is near 90%. [2] Standardly, the average energy capacity for a T-SGES is 35 MWh (varying from 20 MWh to 80 MWh). This figure is based upon a tower arm of 42 m and tower height of 120 m. 5000 blocks equating to 35 tons of composite bricks. [2] The peak power is 4 MW, with a ramp of time of 2.9 seconds. [1] The service lifetime is estimated to be 30 to 40 years. [1]

|

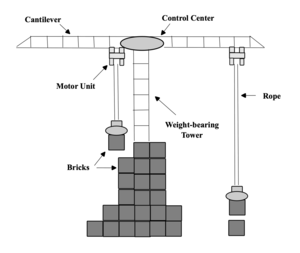

| Fig. 3: A diagram of the essential components of a shaft solid gravity energy storage system (Image source: S. Blinkman). |

The S-SGES system, as depicted in Fig. 3, also uses electromechanical motor generation unit. The main difference is that in the shaft, it no longer stacks blocks, but raises and lowers a single mass. In S-SGES significant height difference in considerable mass is required for an effective system. A primary opportunity of SSGES is in retrofitting retired oil drills or mines. [2] Being able to use these pre-establish structures reduces startup cost as well as reducing maintenance cost of the old drills and mines.

The total energy capacity for a T-SGES system is calculated by using the equation [3]

| ES | = | ηS × m g h |

For shafts, the cycle efficiency, ηS, is typically near 80% as well. [3] Although S-SGES systems very in depth and width, the average energy capacity is estimated to be 1-20 MWh. [1] The peak power is theoretically claimed to be 10 MW, although no specifications of well depth or mass are provided, with no stated ramp up time. [1] The service lifetime is estimated to be over 50 years. [1]

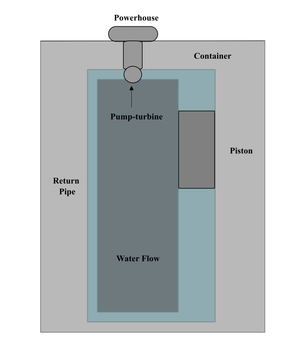

Finally, the P-SGES, depicted in Fig. 4, is unique given it utilizes water in addition to a singular mass. A pump-turbine is utilized instead of a motor generation unit.

|

| Fig. 4: A diagram of the essential components of a piston solid gravity energy storage system (Image source: S. Blinkman). |

The total energy capacity for a P-SGES system is calculated using the equation [4]

| EP | = | ηP × ρVP × g h |

where ρ is the density of the piston material and VP is the volume of the piston.

A typical cycle efficiency, ηP, is 80-90%. [4] Like the S-SGES, P-SGES systems very in depth and width; however, and estimated average energy capacity is 10 MWh, based upon a 1836 tonnes weight and depth of 1000 m. [4] These systems are designed to have piston diameters in the range of 30-100 m, shaft depths of 100-1000m, with the piston length exactly half of the shaft length. [4] The peak power is estimated as 40 MW, with no stated ramp up time. [4] The service lifetime is estimated at 40 years. [1]

The T-SGES is the most geographically adaptable and scalable. They only require the construction of a mechanical structure and transportation of solid objects. The main drawback is they are limited by the mechanical strength of the structure. Of the three structures discussed, it has the largest energy capacity.

The P-SGES is the second most geographically adaptable. The drawback is a high upfront cost for development and the need for water as an agent. It bolsters the best cycle efficiency, but an average energy capacity between the T-SGES and S-SGES.

Lastly, the least geographically adaptable is the S-SGES. The system is exclusively built in retired oil drill sites, of which there are nearly 14,000 suitable installation sites worldwide. [1] The benefit of being able to use these wells are low upfront cost, and support from many organizations to clean and repurpose abandoned drilling sites. The S-SGES has the best service lifetime.

In conclusion, solid gravity energy storage systems are emerging alternatives to pumped hydro energy storage systems. They have the means to address issues related to geographical adaptability and scalability. In the recent years, there has a surging interest in studying and building these systems. In the future, gravity energy storage systems are likely to beginning take up all more significant percent of the world energy storage capacity. Like driving through fields of wind farms, one day there will be driving through fields of tower solid gravity farms.

© Shane Blinkman. The author warrants that the work is the author's own and that Stanford University provided no input other than typesetting and referencing guidelines. The author grants permission to copy, distribute and display this work in unaltered form, with attribution to the author, for noncommercial purposes only. All other rights, including commercial rights, are reserved to the author.

[1] W. Tong et al., "Solid Gravity Energy Storage: A Review," J. Energy Storage 53, 105226 (2022).

[2] A. Fyke, "The Fall and Rise of Gravity Storage Technologies," Joule 3, 625 (2019).

[3] J. D. Hunt et al., "Underground Gravity Energy Storage: A Solution For Long-Term Energy Storage," Energies 16 826 (2023).

[4] C. D. Botha and M. J. Kamper, "Capability Study of Dry Gravity Energy Storage." J. Energy Storage 23, 158 (2019).