|

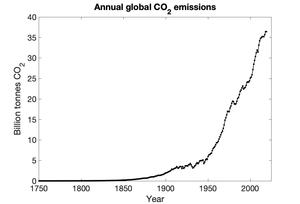

| Fig. 1: Global CO2 emissions by year. [1] (Source: E. Mueller) |

Despite global efforts to transition away from burning fossil fuels towards clean renewable energy sources, global CO2 emissions continue to rise as shown in Fig. 1. It is becoming increasingly apparent that achieving global climate goal will require the deployment of negative emissions technologies. It is estimated that to prevent a warming of 2°C from preindustrial levels, 10 billion tonnes of CO2 (10 GtCO2 = 1.0 × 1013 kg CO2) will need to be removed annually up to 2050, and 20GtCO2 removed each year between 2050 an 2100. [2] Meeting this rate will likely require deployment of several carbon removal technologies. One such method that has gained attention from the private sector is direct air capture (DAC).

There are many different DAC methods being studied and developed, however the two methods that are furthest along in development and are being pursued commercially to meet climate goals are liquid solvent DAC and solid sorbent DAC. The general operating principle of the two methods is the same: CO2 is removed from ambient air by contact with a basic solution (liquid solvent DAC) or a porous basic solid (solid sorbent DAC). Heat is then applied to the capture media which releases the CO2 into a reservoir and regenerates the capture media for another capture cycle. The captured CO2 can be used in a variety of industries, however many of the commercial uses of CO2 are either not scalable or do not contribute a net removal of carbon from the atmosphere,(i.e. carbon used in soft drinks is eventually reemitted into the atmosphere). Therefore, the greatest potential for DAC as a negative emission technology is through geological sequestration of CO2.

The energy requirements for operating DAC systems involves thermal energy for heating/regenerating the CO2 capture media and electricity for powering fans and vacuum pumps. Both solid sorbent and the liquid solvent systems have similar energy demands of 6 GJ per tonne of CO2 captured (GJ/tCO2) of thermal energy and ~1.5 GJ/tCO2 electricity. [3] However, a notable difference is the minimum temperature required for regeneration of the capture media. Solid sorbent systems require heat sources at ~100 °C, while liquid solvent systems require heat sources around 900 °C. [3]

An important metric to assess the economic viability of DAC technologies is the total cost to remove 1 tonne of CO2 from the atmosphere. For this metric, it is important to consider the emissions resulting from the carbon capture process which effectively reduces the carbon offset potential of the DAC capture/regeneration cycle. Therefore, two cost parameters are commonly reported: (1) the gross cost of capture and (2) the net removed cost of capture. The gross cost includes the capital and operating cost of the DAC process and indicates the cost of capturing 1 tonne of CO2 from the air and delivering it for end use or geological storage. The net removed cost accounts for all emissions resulting from the capture process. In this way the net removed cost indicates the total cost to achieve net removal of 1 tonne of CO2 from the atmosphere throughout the process cycle. The gross cost and net cost are related by a take-back factor, x, which indicates the amount of CO2 emitted from the process, in tonnes, per tonne of CO2 captured from the air. The relationship between the gross cost and net cost is shown in Eq. (1). [3]

|

(1) |

|

| Fig. 2: Hellisheidi geothermal power plant outside Reykjavik, Iceland which powers the Climeworks Orca commercial DAC plant (Source: Wikimedia Commons |

The estimated cost for DAC facility with geological sequestration with a capacity of 100ktCO2/year is ≤ $300/tCO2. [4] Of particular importance for minimizing the net removed cost is using a low carbon heat source. Cost estimates were compared for solid sorbent DAC plants using three different energy sources: (1) natural gas (2) geothermal (3) nuclear. The estimated gross cost of capture is $223, $205, and $233/tCO2 for natural gas, geothermal, and nuclear respectively. [4] However, by using a low carbon energy source, the take-back factor was reduced from 0.65 for the natural gas scenario to 0.29 for the geothermal and nuclear scenarios. As a result, the estimated net removed cost for the natural gas scenario is $637 compared to $289 for geothermal energy and $328 for nuclear energy. [4] Currently, the largest DAC facility, located near Reykjavik, Iceland and operated by Climeworks, is capable of processing several thousand tonnes of CO2 per year and is powered by the nearby Hellisheidi geothermal power plant shown in Fig. 2. However, the reported net removed cost for the Climeworks facility is currently around $600/tCO2. [3] The cost reductions reported in McQueen et al. for large ≥ 100ktCO2/year DAC includes efficient scaling of plant size and reduced capital costs through standardized manufacturing of DAC components. [4]

To measure the economic viability of DAC technology, it is worth comparing the carbon removal cost to the natural approach of planting trees to sequester carbon. Most analyses report costs of sequestration through reforestation to be less than $100/tCO2. [5] Therefore, the current cost to capture and store CO2 using DAC is not competitive with reforestation methods. In addition, the market for CO2 for industrial use is too limited for ≥ 1 MtCO2/year DAC plants to be profitable. Therefore, policies have been created to promote scale up of DAC facilities by incentivizing CO2 for industrial use to be sourced from DAC. The hope for these programs is that by creating a scalable market for DAC sourced CO2, DAC companies can scale their facilities and employ cost-reducing innovations that will allow DAC with geological sequestration to be competitive as a negative emissions technology over the coming decades.

Under the US federal tax code 45Q, DAC facilities that remove ≥ 100ktCO2/year for storage or beneficial reuse are eligible for tax credits of up to $50/tCO2 depending on the end use. [4] The largest market for CO2 is in enhanced oil recovery (EOR). However, DAC would have to compete with current CO2 suppliers to the EOR industry which currently charge $10-40 tCO2. [4] Therefore, the 45Q tax incentive alone is unlikely to cover the gap between the cost of DAC and current CO2 prices.

A recent DAC incentive was included in California's Low Carbon Fuel Standard (LCFS) which provides credits for DAC for geological sequestration including EOR. Between 2018-2019, the credits were traded between 172-188 $/tCO2. [4] Considering the cost estimates for large scale commercial DAC plants, the LCFS incentive in combination with the 45Q tax credit may lead to commercial partnerships necessary to scale up the DAC industry in the decades to come.

© Eli Mueller. The author warrants that the work is the author's own and that Stanford University provided no input other than typesetting and referencing guidelines. The author grants permission to copy, distribute and display this work in unaltered form, with attribution to the author, for noncommercial purposes only. All other rights, including commercial rights, are reserved to the author.

[1] P. Friedlingstein et al., "Global Carbon Budget 2020," Earth Syst. Sci. Data, 12, 3269 (2020).

[2] Negative Emissions Technologies and Reliable Sequestration: A Research Agenda (The National Academies Press, 2019).

[3] N. McQueen et al., "A Review of Direct Air Capture (DAC): Scaling Up Commercial Technologies and Innovating for the Future," Prog. Energy 3, 032001, (2021).

[4] N. McQueen et al., "Cost Analysis of Direct Air Capture and Sequestration Coupled to Low-Carbon Thermal Energy in the United States," Environ. Sci. Technol 54, 7542 (2020).

[5] S. G. Hernandez and S. W. Sheehan, "Comparison of Carbon Sequestration Efficacy Between Artificial Photosynthetic Carbon Dioxide Conversion and Timberland Reforestation," MRS Energy Sustain. 7, E32 (2020).