|

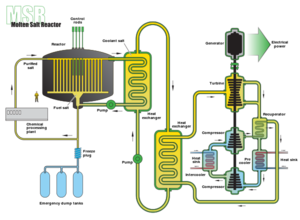

| Fig. 1: This figure shows the layout of a Molten Salt Reactor that uses conduction and a freeze plug system for two levels of passive heat removal. (Source: Wikimedia Commons) |

Passive heat removal in nuclear reactors is the concept that when a reactor encounters an emergency, such as loss of coolant flow, it will be able to shut itself down safely without intervention, human, electrical or mechanical. The International Atomic Energy Agency has classified four levels of passive safety methods, A to D, based on the likelihood of successful shutdown in all emergency situations . Category A reactors rely on no motion of fluids or mechanisms to remain passively stable, while Category D reactors are one the border of active and passive, often requiring battery power and mechanical actuation. [1] Passive heat removal systems will play an integral role in the future of nuclear energy safety.

These techniques often include convection of large masses of liquid metal, gravity, material properties catalyzing an reaction (physical or mechanical), and pressure differentials. Depending on the type of fuel, cooling and energy generation methods, different safety factors need to be put in place to prevent overheating and non-regulated reactions. [2] In mechanical systems it is often necessary to design for a safe failure method, a concept called DFMEA (Design Failure Mode and Effect Analysis), these principles are being applied to preventing meltdowns in nuclear reactors.

In the case of MSRs, which I previously wrote about, the negative coefficient of reactivity generally prevents overheating due to convection, but in a catastrophic situation if the tank of fuel overheated, freeze plugs would melt and the fuel would drain a passively cooled dump tank (Fig. 1). The freeze plugs are made of a material that requires active cooling to remain solid, so a cut in power will cause the reactor to shut itself down. These safety factors will prevent catastrophe in the next generation of nuclear power plants.

Another safety factor implemented is enclosing the reactor in a large sodium bath, used as a heat sink to prevent overheating and to provide the convective benefits to light water reactors. Reducing the amount of pressurized water in these reactors and adding an atmospheric pressure sodium salt bath prevents large amounts of radioactive material to be released into the atmosphere in the event of tank rupture, as the low pressure salts take most of the thermal gains from the reactor. [3] This is one way passive cooling can be applied to current light water reactors.

Next generation reactors will become safer and less likely to result in catastrophic environmental damage because of passive safety features which reduce the likelihood of high potential energy release situations. Passive heat removal techniques can also be applied to light water reactors to prevent meltdowns and catastrophic failure.

© Joe Sunde. The author grants permission to copy, distribute and display this work in unaltered form, with attribution to the author, for noncommercial purposes only. All other rights, including commercial rights, are reserved to the author.

[1] "Safety Related Terms for Advanced Nuclear Plants," International Atomic Energy Agency, IAEA-TECDOC-626, September 1991.

[2] L. Burgazzi, "Reliability of Passive Systems in Nuclear Power Plants," in Nuclear Power - Practical Aspects, ed. by W. Ahmed (InTech, 2012).

[3] B. M. Elsheikh, "Safety Assessment of Molten Salt Reactors in Comparison with Light Water Reactors", J. Radiat. Res. Appl. Sci. 6, 63 (2013).