|

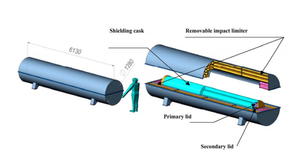

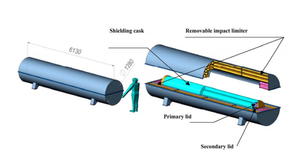

| Fig. 1: Design Assembly Scheme for a Type C cask. [9] (Courtesy of the U.S. Department of Energy.) |

Transportation is an important part of the supply chain across the nuclear fuel cycle. Whether it is from mines, enrichment facilities, nuclear power plants, or used fuel storage facilities, transportation of raw materials and waste products to and from these facilities is necessary. At each stage, these nuclear fuel cycle materials have different levels of radioactivity and various measures need to be taken to ensure safe movement of such goods such that they pose minimum or no risk to the people and their environment. These radioactive materials are transported both nationally and internationally via public roads, railways and seas. This paper aims to discuss the methods, designs and safety regulations surrounding such logistics.

The nuclear fuel cycle can be divided into three main stages. First, the front-end, which starts from mining of uranium ore and ends at the delivery of fabricated fuel elements to the fuel site. The next stage involves the storage of fresh fuel at the reactor site and the spent fuel after removal from the reactor core on site. Finally, the back-end, which starts with the spent fuel transported away from the reactor storage, and ends with reprocessing and disposal of nuclear waste.

Uranium ore concentrate is a material of low radioactivity and does not pose serious radiological hazard. Just like most heavy metal compounds, it is toxic and can be harmful if ingested. It is packaged in sealed 205-liter steel drums and is required to meet the Industrial-Packaging 1 requirements. [1] It is generally transported in sealed steel drums with tight-fitting lids meeting the UN design standards for stowage, handling and package integrity. The drums are loaded into general-purpose freight containers securely stowed to prevent movement or load shifting during handling or transport, and all containers must comply with the International Convention for Safe Containers.

Uranium Hexafluoride is also of low activity and the radiological risk is not significant but any person exposed to the release may suffer due to the chemical toxicity. In conformity with international regulatory practice for "dangerous goods" transport, UF6 is classed as having subsidiary risk. It is also transported in solid form below atmospheric pressure in cylinders, as a release would result in an immediate chemical reaction with air moisture. These cylinders are 48 inch in diameters, weigh about 2.5 tones, are 12 feet in length and can hold up to 12 tones of UF6. [2] There are a series of regulations surrounding the handling of these cylinders. Firstly, they have to go through tests such a hydrostatic strength test and Pneumatic leak test, but not necessarily a fire test. Also, each cylinder must be adequately marked according to ISO standards. [3]

These are manufactured at Fuel fabrication plants and are made up of ceramic pellets formed from pressed uranium oxide that has been sintered at very high temperatures of over 1400 degree Celsius. The Pellets are aligned with long, hollow, metal rods, which in turn are arranged in fuel assemblies - ready to go into the reactor. Usually, trucks holding up to 6 tones of fuel are used to transport uranium fuel assemblies, however, in some parts of the world, rails may also be used. The precision-made fuel assemblies are specifically designed to protect them from damage during transportation in accordance with the IAEA safety standards. [4]

Amongst all nuclear fuel materials, transportation of used nuclear fuel is perhaps most crucial. When taken out of a nuclear power reactor, its composition is 96% uranium, 1 3 % fission products and 1% plutonium. Used fuel emits very high levels of radiation and heat, and is therefore stored in water pools on site for about six months before it can be transported to an interim storage site or a reprocessing plant. This spent nuclear fuel is shipped in sturdy containers that provide physical protection, containment, shielding, heat management, and nuclear criticality safety. These containers are referred to as transport casks, and are transported via truck as well as rail.

The typical specification of a truck cask used for spent nuclear fuel is- Weight: 25 tons, Cask Diameter: 4 feet, Overall Diameter including impact limiters: 6 feet, length: 20 feet and capacity: up to 4 PWR or 9 BWR fuel assemblies. Whereas the typical specification of a rail cask that will be used for such purposes are: Weight: 125 tons, Cask Diameter: 8 feet, overall diameter including impact limiters: 11 feet, overall length: 25 feet and capacity: up to 37 PWR or 87BWR fuel assemblies. On comparing the capacities, we can see that rails are a lot more efficient. [5]

Under the IAEA regulations, these casks are subject to several tests to ensure safety. Firstly, a two-drop test - a 9-meter drop onto an unyielding surface and a 1-meter drop onto a steel punch bar. Next, a fire test in which the package is subjected to a fully engulfing fire of 800 degree Celsius for 30 minutes, and finally an immersion test where the cask is subjected to conditions equivalent to a 15 meter submersion for 8 hours. These tests ensure that the casks can withstand transport accidents involving crashes, fires or submergence which can be realistically envisaged, and in the case of fissile materials, to ensure that an unwanted chain reaction does not occur. [6]

These are large vessels built specifically for moving used fuel from reactors to interim storage facilities across seas, and can carry up to 17 used fuel flasks. For safety, they have double hulls with impact-resistant structures between the hulls, together with duplication and separation of all essential systems such as navigation, communication, cargo monitoring, cooling systems and even twin propellers and twin independent engines to provide high reliability and increased chances of survival in case of a mishap. Following the International Maritime Organization, each of these ships follow an international safety standard known as International Code for the Safe Carriage of Packaged Irradiated Nuclear Fuel, Plutonium and High-Level Radioactive wastes on Board ships (INF code). Depending upon the total radioactivity of INF cargo that is carries on board, the ships are classified as class 1, class 2 or class 3 INF ships. [7]

It may be the case that transportation of spent nuclear fuel in some cases may only be feasible via air due to location or political conditions. The IAEA has already established a regulatory framework to certify air transport Type C casks, although no such cask has been built or certified yet. [8] In the absence of Type C casks, type B casks have been used under an exemptions and special arrangements for administrative and security controls. However, in the last 20 years, technology improvements have enabled aircrafts with increasingly heavy-lift capability to be deployed. As a consequence, now, the size and weight of type C casks are well within the bounds of such aircraft's capability. Presently, cost is the only factor that acts as a deterrent as it is 3 times as expensive to use air transport for SNF as rail, but the scenario might soon change with reduction in costs. [9]

© Yash Poddar. The author grants permission to copy, distribute and display this work in unaltered form, with attribution to the author, for noncommercial purposes only. All other rights, including commercial rights, are reserved to the author.

[1] I. J. Hunter, "The Nuclear Fuel Cycle: Radioactive Materials Packaging and Transportation," J. Radiol. Prot. 13, 279 (1993).

[2] "Interim Guidance on the Safe Transport of Uranium HexaFluoride," International Atomic Energy Agency, IAEA-TECDOC-609, June 1991.

[3] "Nuclear Energy - Packaging of Uranium Hexafluoride (UF6) for Transport," International Organization for Standardization, ISO 7195:2005, (2005).

[4] "Nuclear Fuel Cycle Information Systems," International Atomic Energy Agency, IAEA-TECDOC -1613, April 2009.

[5] E. Supko and M. H. Schwartz, "Overview of High-Level Nuclear Waste Materials Transportation: Processes, Regulation, Experience and Outlook in U.S.," Energy Resources International, ERI-2030-1101, January 2011.

[6] "Operation and Maintenance of Spent Fuel storage and Transportation Casks/Containers," International Atomic Energy Agency, IAEA-TECDOC-1532, January 2007.

[7] "The INF Code and Purpose-Built Vessels," World Nuclear Transport Institute, March 2013.

[8] "The Air Transport of Radioactive Material in Large Quantities or with High Activity," International Atomic Energy Agency, IAEA-TECDOC-702, April 1993.

[9] M. J. Haire et al., "Air Transport of Spent Nuclear Fuel Assemblies," Oak Ridge National Laboratory, 25 Feb 07.