|

| Fig. 1: Experimental Breeder Reactor-II, built in Argonne National Laboratory. (Source: Wikimedia Commons) |

The Integral Fast Reactor (IFR), also known as Advanced Liquid-Metal Reactor, is a fast neutron reactor with a very efficient and clean nuclear fuel cycle. It was once a very active research project of the U.S. Department of Energy, and even a prototype (called Experimental Breeder Reactor-II) was build in Argonne National Laboratory. However, the project was hampered in 1994 after a series of controversies involving safety issues and nuclear non-proliferation policies. [1] More recently, in 2002, the Integral Fast Reactor was elected the best nuclear reactor design in a Department of Energy report, even though there are no IFR in commercial use today. [2] Here, we analyze how a fast reactor works, focusing on the qualitative comparison with the more common thermal reactors, and assess the safety issues which are at the core of their unsuccessful spreading.

They are free neutrons with a kinetic energy on the order of 1 MeV, which corresponds to a speed of around 13,815 km/s, according to the expression for the relativistic kinetic energy EKE = (γ - 1) m0c2, where γ is the Lorentz factor and m0 the rest mass. These neutrons have intermediary speed between thermal neutrons (which are in thermal equilibrium with the background) and higher-energy neutrons in particle accelerators and cosmic rays. Fast neutrons can be produced either by nuclear fusion or fission (although these processes produce neutrons following a Maxwell distribution with mode energy usually below 1 MeV, so that most of the neutrons produced do not qualify as "fast". [3]

Almost all thermal reactors currently in use are thermal reactors, which means that they make use of a moderator (regular water in light-water reactors, heavy water in heavy-water reactors, graphite in gas-cooled reactors etc) to slow down fast neutrons into thermal neutrons. This is necessary because the cross section of fissible nuclei (e.g. U-235, Pu-239, Pu-241) is inversely proportional to the bombarding neutron energy (roughly, the fissible atom vibrates proportionally to its absolute temperature, and thermal neutrons are ideal for their fission since they are at the same temperature as the surrounding material). On the other hand, the cross section for fertile nuclei (a fertile isotope is one that is not fissionable by thermal neutrons, but can be converted to fissile material if the neutrons have high enough kinetic energy; e.g. U-238 to Pu-239) is directly proportional to the neutron energy. Unfortunately for thermal reactors, natural uranium contains approximately 99.28% of fertile U-238 isotope and only 0.71% of fissile U-235. As a result, making sure that neutrons are thermalized maximizes the probability that a given neutron will be captured by fissile material, allowing thermal reactors to use low-enriched (or even natural, in the case of heavy-water reactors) uranium. [3]

Fast reactors dispense the use of a moderator and make use of fast neutrons to sustain the nuclear fission chain reaction. The irony is that U-238 will, at low energies, absorb more neutrons than it consumes (due to the phenomenon of resonance absorption at neutron energies from 1 eV-10 keV). Therefore, U-238 cannot be made "critical", and fast neutron reactors need higher ratio of fissile-to-fertile material (i.e. higher enrichment) to ignite the nuclear reaction. Despite this drawback, once the chain reaction achieves criticality, fast fission reactions have a larger neutron output, and fast neutrons are more likely than thermal neutrons to cause fission once they are absorbed. This makes fast reactors capable of achieving a so- called "breeding" condition, in which they generate more fissible material than they consume. [3,4]

|

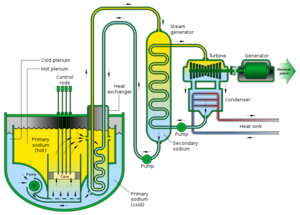

| Fig. 2: Basic Schematic of a sodium-cooled fast reactor. (Source: Wikimedia Commons) |

Basically, fast reactors can achieve "breeding" condition by transmuting fertile U-238 into fissible Pu-239 with fast neutrons. This is more sufficient to replace the consumed U-235 i.e. fast reactors can produce more fissible material than they consume. Once the reaction has achieved critically (which, again, requires relatively high enriched starting fuel), the breeder reactor can be continuously re-fueled with natural uranium. This makes fast reactors extremely fuel-efficient: they are capable of extracting nearly all the energy in the fuel (in contrast, thermal reactors are typically able to extract less than 10% of the energy in the enriched uranium). [4,5]

More than that, fast reactors are able to fissile the actinides resulting from Pu-239 fission (which are all fissible with fast neutrons) into non-radiative or radiative elements with short half-live. These actinides are the core component of unrecyclable nuclear waste in thermal reactors. In thermal reactors, even though around 1/3 of the output energy actually comes from Pu-239 (originated from fertile U-238) consumption, this is not sufficient to stop the build-up of reactor-grade plutonium (even mass number plutonium isotopes which are not fissible) and of high concentrations of nasty actinides in the reactor. [6]

Therefore, fast reactors are much cleaner than conventional nuclear reactors in terms of not generating hazardous nuclear waste. Specifically to the IFR, pyroelectric (voltage generation with heat) separation is used to remove the transuranic (elements with higher atomic number Z than uranium) and concentrate them; they are then used to re-fuel the reactor. [5]

Controversies that led to the hampering of the IFR project were largely centered on safety considerations. [1] One worry about fast neutron reactors is the lack of moderators, which in thermal reactors serves as negative feedback in case the reaction rate raises too much (basically, increasing reaction leads to increasing temperatures, which leads to moderator boiling, which leads to less thermalized neutrons, which leads to smaller reaction rate). Therefore, in fast reactors it is necessary to find a substitute capable of providing negative feedback. [7] This can actually be achieved by reactor design, since the fuel and cladding expansion at higher temperatures, which allows more neutrons to escape the core, can stop the chain reaction and provide negative feedback.

Another concern about the safety of fast reactors comes from the coolant, which carries the thermal energy generated by fission to the water to be boiled to move the steam turbines. Thermal reactors can use the moderator (usually water) as a coolant, but fast reactors must use coolants other than water. Typically, fast reactors use liquid metals as coolants (namely, sodium and lead). For one thing, using a liquid metal coolant has the advantage of being able to maintain the core of the reactor at lower pressures (in fact, at ambient pressures), since they have boiling points much higher than water (883 °C for Na, 1749 °C for Pb). [3] In water reactors, the pressure has to be maintained extremely high to keep water liquid even at high temperatures. However, using liquid metal coolants has important drawbacks. Integral fast reactor usually uses liquid sodium as coolant, which is highly reactive: it ignites when in contact with air and explodes when in contact with water. This problem has already caused reactor accidents in the past (e.g. Monju Nuclear Power Plant in Japan was forced to shutdown in 1995 after sodium leakage) and has contributed to the hampering of fast reactors. [1] It is possible to overcome this problem and ensure safety by engineered safety mechanisms (e.g. a coolant loop between reactor and steam turbines). Using lead as the coolant is still not a very practical alternative, since lead's very high melting point and vapor pressure makes it very difficult to refuel and service a nuclear reactor. [7]

© Idel Waisberg. The author grants permission to copy, distribute and display this work in unaltered form, with attribution to the author, for noncommercial purposes only. All other rights, including commercial rights, are reserved to the author.

[1] C. E. Till, Y. I. Chang and W. H. Hannum, "The Intergral Fast Reactor - An Overview," Prog. Nucl. Energy 31, 3 (1997).

[2] "A Technological Roadmap for Generation IV Nuclear Energy Systems," U.S. DOE Nuclear Energy Research Advisory Committee, GIF-002-00, December 2002.

[3] "DOE Fundamentals Handbook - Nuclear Physics and Reactor Theory, Volume 2 of 2," U.S. Department of Energy, DOE-HDBK-1019/2-93, January 1993.

[4] C. E.Till and Y. I. Chang, Plentiful Energy: The Story of the Integral Fast Reactor (CreateSpace Independent Publishing Platform, 2011).

[5] C. Archambeau et al., "The Integral Fast Reactor (IFR): An Optimized Source for Global Energy Needs," Science Council for Global Initiatives, February 2011.

[6] B. W. Brook, T. Blees and W. H. Hannum, "Nuclear Waste: Use Fast Reactors to Burn Plutonium," Nature 486, 7403 (2012).

[7] G. Kessler, Sustainable and Safe Nuclear Fission Energy Power Systems (Springer, 2012), pp 417-420.