|

| Fig. 1: The Tesla Turbine. (Image in the public domain.) |

Nikolai Tesla (b. 1899) was one of the world's most innovative and eccentric inventors who is best known for bringing electricity to the world using his alternating current system. [1] Among his lesser-known inventions is a bladeless turbine-otherwise known as the Tesla turbine- which he patented in 1913. He believed that the turbine would not only have higher efficiencies, but also lower production costs than other turbines. [2]

The Tesla Turbine differs from typical turbines in that instead of using curved blades like those of a windmill, it uses smooth, parallel disks placed evenly across a shaft, like CD's placed along a stick.

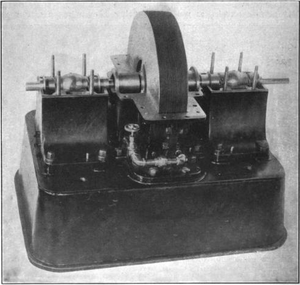

Turbines work by converting the kinetic energy of a fluid into another form of energy. In a wind turbine, the wind (the fluid) causes the blades to rotate. The blades in turn rotate a generator, which converts the rotational energy into electricity. In the Tesla turbine, the smooth disks spin to generate energy (Fig. 2A), as opposed to the blades in the wind turbine.

|

| Fig. 2: A) The flow of fluid causes the disks and the shaft to rotate, which generates energy. B) The initial flow of fluid is tangential to the disks. C) The direction of the fluid spirals towards the center in between two disks and exits through the central vent holes (central vent holes not pictured). (Source: "Wikipedia Commons".) |

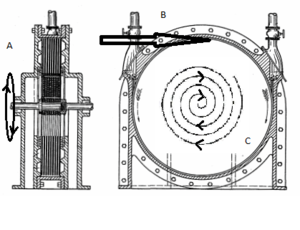

What causes the disks to spin is the exchange of momentum between the fluid and the disks. A stream of fluid (air, water, etc ...) is sent tangentially in between the disks (Fig. 2B). The molecules of fluid closest to the disk will interact with the molecules of the metal, essentially adhering to the surface. This creates a theoretically stationary layer called the boundary layer. The layer above (the second layer) will be slowed down by the molecules of the boundary layer (the first layer), and the third layer will be slowed down by the second layer, and so on. The amount of slowing down decreases from layer to layer, so the layers closer to the plate are slower than those directly in between the two plates. This creates something called laminar flow, in which the fluid flows in parallel layers without turbulence (Fig. 3).

The faster movement of the higher layers against the slower movement of the layers below creates a drag from viscous shear forces. This causes the lower layers to drag along with faster higher layers, which ultimately causes the disks to spin. The fluid spirals toward the center from the outer edge of the disk to the central vent holes (Fig. 2C). [3]

Though Tesla projected efficiencies of up to 97%, the reported efficiencies tend to be around 40%. Warren Rice, an Emeritus professor at Arizona State University, has done extensive work on the Tesla turbine and stated several problems with the turbine. First, is that "in order to attain high rotor efficiency, the flowrate number must be made small, which means high rotor efficiency is achieved at the expense of using a large number of disks, and hence a physically large rotor." Additionally, "with common fluids, the required disk spacing is dismayingly small, causing laminar-floow rotors to tend to be large and heavy for a prescribed throughflow rate." He also stated that are inherent losses in the flow of fluid entering and exiting the rotor. Even if the rotor is completely efficient, the inefficiencies of the entrance and exit of the fluid could compromise the overall efficiency. [4]

|

| Fig. 3: Laminar flow of distinct layers. The layers towards the bottom are slower than those near the middle. |

Despite its inefficiencies, the Tesla turbine still has several advantages. The production costs for disks are much lower than for blades, and the overall design is simpler and more easily manufactured. Additionally, the turbine can be used for a variety of fluids without extensive damage to the disks. These include mixtures with solids, liquids, and gases, as well as viscous fluids, non-viscous fluids, and both Newtonian and non-Newtonian fluids. The flow of fluid in the turbine can also be reversed into a pump, and the disks do not suffer from cavitation issues that bladed turbines often have. [5] These features lend themselves well to potential uses in the generation of power from geothermal steam and particle-laden industrial gas. [4] Other potential uses include blood pumps as well as in wind turbines. [6,7] Though the Tesla turbine has not yet proven to be more effective than traditional turbines, there are still potential practical uses.

© Spencer Nam. The author grants permission to copy, distribute and display this work in unaltered form, with attribution to the author, for noncommercial purposes only. All other rights, including commercial rights, are reserved to the author.

[1] W. B. Carlson, "Inventor of Dreams," Scientific American, 21 Feb 05.

[2] N. Tesla, "Fluid Propulsion," U.S. Patent 1061142, 6 May 1913.

[3] J. A. K. Ackroyd, B. P. Axcell and A. I. Ruban, eds., Early Developments of Modern Aerodynamics (Elsevier, 2001), p.77.

[4] W. Rice, "Tesla Turbomachinery," in Handbook of Turbomachinery, ed. by E. Logan, Jr. and R. Roy (Marcel Dekker, 2003), p. 861.

[5] A. K. Chattopadhyay, D. N. Roy, and G. Biswas, "Radial Flow of a Viscous Fluid Between Two Coaxially Rotating Discs," Indian J. Technol. 29, 221 (1991).

[6] E. G. Miller, B. D. Etter and J. M. Dorsi, "A Multiple Disk Centrifugal Pump as a Blood Flow Device," IEEE Trans. Biomed. Eng. 37, 157 (1990).

[7] H. J. Fuller, "Wind Turbine for Generation of Electric Power," U.S. Patent 7695242, 13 Apr 10.