|

| Fig. 1: Location of the Grosmont Carbonates. [1] (Courtesy of the Alberta Energy Resources Conservation Board) |

The Alberta Grosmont Carbonate Formation is a massive deposit of currently unexploited heavy oil/bitumen resource located in Northern Alberta (Fig. 1). [1] It is the most significant (71% in terms of OOIP) between four major carbonate reservoirs, which include Nisku, Shunda and Debolt. [2] While estimated to contain about 64.5 billion m3 (~400 billion barrels) of original oil in place (OOIP) across an area of 1,766 thousand hectares, no reserves (defined as oil resources that are recoverable by current technology at the current oil price) have been booked as there are currently no known full scale commercial operations beyond a few test pilots. [1] Note that most estimates are made using cut- offs, which are minimum thresholds that a reservoir must meet in order to be counted as a resource. In this case, it is minimum porosity value of 8% and a minimum initial oil saturation of 50%. [1] While these are reasonable quantities, it is possible an upward revision can take place as the extent of the reservoir is discovered and as technological advances make resources that fall below these minimum values technically recoverable.

The reservoir has an average thickness of 23.8 meters and 20% porosity (or void space in the rocks where fluids such as oil can reside). [1] Out of the 20% porosity that it contains, about 79% is oil while 21% is water. In petroleum terms, the average initial oil saturation is 79%. [1,2] Carbonate reservoirs are very heterogeneous in nature, with the Alberta carbonates containing a triple porosity system including a base rock matrix, vugs (relatively large holes in the rock matrix) and fractures.

|

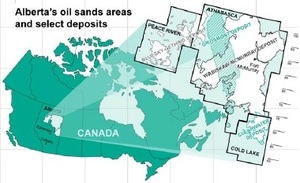

| Fig. 2: Isopach Map of the Grosmont Carbonates (Thickness of the Formation Over the Area). [1] (Courtesy of the Alberta Energy Resources Conservation Board) |

The Grosmont Formation was deposited about 380 million years ago in the late- Devonian period in an open shallow limestone marine shelf environment. [3] The thickness is variable from 10 m to a maximum of 200 m and the formation is effectively sealed by overlying siltstones from the Lower Winterburn Group and underlying shaly limestones from the Lower Ireton Formation. [3] Usually, four individual zones are identified, namely Grosmont A, B, C and D. [1] After deposition of calcium carbonates from living organisms, they were compacted (turned into limestone) and were exposed and dissolved by water. Due to this dissolution, magnesium slowly replaced the calcium, which changes limestone into dolomite. [3] This forms karsts, vugs, channels and caverns, which makes characterization of the formation very difficult with pore spaces ranging from micron-scale matrix pores to centimeter scale vugs and fractures. [4] Oil then presumably migrated from source rocks and was then biodegraded into the very heavy viscous oil that exists today. [3] Due to this depositional environment, it is a vast, regional deposit that is both vertically thick and wide in extent. [1] (Fig. 2)

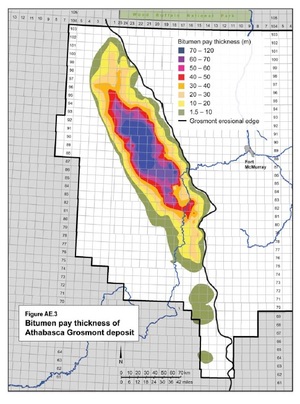

The initial pilot projects, which are small scale operations that are used to test possible recovery schemes for full-field development, have been carried out from 1970-1980s including steam flooding, cyclic steam injection and in situ combustion. [2] Steam flooding uses several vertical wells where steam is injected in some and oil is produced in others, usually in a pattern. Cyclic steam injection (CCS) is a single well technique (but is scaled up by utilized multiple wells) wherein steam is injected in the well, shut-in for a soaking period and finally opened up to produce oil (Fig. 3). [5] In-situ combustion injects air into the formation to burn some of the oil underground and produce heat in the formation. The main driver in increasing the temperature is the need to decrease the viscosity. [6] At normal temperatures, oil sands can vary from the consistency of peanut butter to that of asphalt but can be reduced to values in line with molasses to mineral oil at elevated temperatures.

Analyses of initial pilots from Buffalo Creek and McLean have been contradictory. [2] On the other hand, a peak rate of up to 440 bbls/d from a single vertical well was achieved with a very low steam-oil ratio of 3.65, which indicates encouraging potential for field scale recovery. [7] On the other hand, uneven conformance (uneven displacement of the oil by steam leading to steam/water being produced in the wells instead of oil) with steam flood especially in McLean led to the failure of several pilots, with their production dropping to only 5 bbl/d relatively quickly. [2,7] Other pilots failed due to operational issues. [7]

Current published techniques still require the injection either of steam or solvent in order to reduce the viscosity of the in-situ fluid.

|

| Fig. 3: Illustration of the Cyclic Steam Stimulation Process. [5] (Courtesy of the Canadian Association of Petroleum Producers) |

Thermal pilots and studies are ongoing, with increasing emphasis in using CSS and SAGD (Steam-Assisted Gravity Drainage). Computer simulations seem to indicate possible economic recovery of oil using SAGD, which has been extensively used in other areas of the Canadian Oilsands. [7] A novel method is also being developed by Shell Canada, using electric heaters to convert the bitumen to light oil underground and then efficiently producing the low viscous "upgraded" oil to the surface after considerable heating. [8]

Solvent injection relies on the injection of a less viscous liquid or gas that is fully or partially able to mix (i.e. partially or fully miscible) with the oil in place and therefore reduce the overall resulting mixture. It is theorized that fractures can transport the solvent quickly and the high matrix permeability can allow for quick solvent mixing in the bulk of the formation. [4] Core testing seems to indicate good response in core-scale (centimeter-scale) tests, with over 60% of the original oil produced, with positive indications from their pilot facility. [4] However, solvents are generally very expensive and thus any such enhanced oil recovery processes will require high oil prices and/or very efficiency production strategies. Thermal and solvent methods can be combined by co-injecting solvent with the steam in order to enhance the effects of thermal recovery. Pilots are currently being done by Laricina using this technology, with encouraging results, showing up to 807 bbl/d of production. [9]

Needless to say, there is a considerable amount of work that is required in order for commercial production to commence. A combination of proper geological characterization, accurate reservoir simulation and efficient operations are required in order to execute a technically and economically feasible project in such a complex, heavy oil reservoir. Certain environmental concerns not presented above will need to be addressed with concrete mitigation plans steered by government policies. [10]

© John Lagasca. The author grants permission to copy, distribute and display this work in unaltered form, with attribution to the author, for noncommercial purposes only. All other rights, including commercial rights, are reserved to the author.

[1] "Alberta's Energy Reserves 2011 and Supply/Demand Outlook 2012-2021," Alberta Energy Resources Conservation Board, ST98-2012, June 2012.

[2] M. McDougall, J. M. Alvarez and E. Isaacs, "Alberta Carbonates: the Third Trillion," One Petro 19-0925, July 2008.

[3] B. E. Buschkuele, F. J. Hein and M. Grobe, "An Overview of the Geology of the Upper Devonian Grosmont Carbonate Bitumen Deposit, Northern Alberta, Canada," Natural Resources Research 16, 3 (2007).

[4] N. Edmunds et al., "Prospects for Commercial Bitumen Recovery from the Grosmont Carbonate, Alberta," J. Can. Petrol. Technol. 48, No. 9, 26 (2009).

[5] "The Facts on Oilsands," Canadian Association of Petroleum Producers, 2012-0022, November 2012.

[6] K. R. Alnoaimi, "Heavy Oil Recovery: Definitions and Means," Physics 240, Stanford University, Fall 2010.

[7] J.Y. Yuan et al., "Evolving Recovery Technologies Directed Towards Commercial Development of the Grosmont Carbonate Reservoirs," One Petro, 137941-MS, October 2010.

[8] P. Roche, "Game Changer: Underground Upgrading," New Technology Magazine, June 2008.

[9] B. Tippee, "Laricina: Carbonate SAGD Test, 'Encouraging'," Oil and Gas Journal, 16 May 12.

[10] Y.-C. Jan, "Albertan Oil Sands," Physics 240, Stanford University, Fall 2011.