|

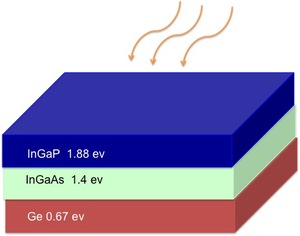

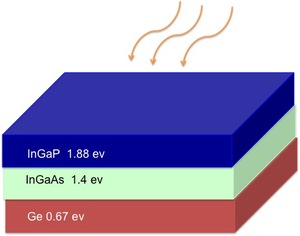

| Fig. 1: Schematic of an InGap/InGaAs/Ge triple junction solar cell. |

Solar electricity, or photovoltaics has shown since 1970s that the we can get a substantial portion of its electrical power without burning fossil fuels (coal, oil or natural gas) or creating nuclear fission reactions. The Sun provides us with a staggering amount of free, environmentally friendly, quiet and reliable energy supply. Solar cells are a promising renewable, carbon-free electric energy resource to address the fossil fuel shortage and global warming. Solar cells are commonly classified as three generations based on the material and the processing technology used to fabricate them. Basic properties of the solar cell including the typical range of efficiencies are determined based on the material used to make them. [1] The energy conversion efficiency of a solar cell is defined as the ratio of the electric power generated by the solar cell to the incident sunlight energy into the solar cell per time .

Silicon wafer-based photovoltaic is the first generation of solar cells, which is the dominant technology for terrestrial applications today. It's accounting for more than 85% of the solar cell markets. Using single-crystalline and multi-crystalline wafers, used in commercial production, approaches power conversion efficiencies up to 25%. But the fabrication technologies at present limit them to about 15 to 20%.

The second generation of photovoltaic materials is based on the use of thin-film deposits of semiconductors. It could be amorphous silicon, cadmium telluride, copper indium gallium diselenide or copper indium sulfide. Manufacturing costs of the thin film solar cells tend to be lower compared to conventional solar cells but the efficiencies of them is also lower, around 6% to 10%. The other advantage of thin film solar cells is the ability of fitting panels on light materials or flexible materials, even textiles because of their decreased mass .

The third generation of photovoltaic cells is the combination of first and second-generation of solar cells advantages. It must increase in efficiency that maintains the cost advantage of second-generation materials. The approaches include dyesensitized nano-crystalline or Gratzel solar cells, organic polymer-based photovoltaics, tandem (or multi-junction) solar cells, hot carrier solar cells, multi-band and thermophotovoltaic solar cells. Compared to all other photovoltaic technologies, multi-junction solar cells have a highest theoretical limit of efficiency conversion. [2] The maximum recorded efficiency of 40.7% achieved by Boeing Spectrolab Inc by using multi-junction solar cell in December 2006. [3]

Multiple materials solar cells with different bandgaps that covers a range of the solar spectrum achieved the highest efficiency conversion. Multi-junction solar cells structure is multi-layers of single-junction solar cells on top of each other. Band gap of the materials form the top to the bottom going to be smaller and smaller. It allows to absorbs and converts the photons that have energies greater than the bandgap of that layer and less than the bandgap of the higher layer. [4] Availability of materials with optimal band gaps that simultaneously allow high efficiency through low defect densities is the fundamental limitation that multi-junction solar cells suffer from that. Very good candidates to solve the problem and to fabricate such multi-junction cells are alloys of groups III and V.

Solar cells made of III-V semiconductor compounds have the potential for high efficiency, their compound materials have advantages including the bandgap tunability by elemental compositions, covering a wide range of solar spectrum, higher photon absorption by the direct bandgap energies, higher resistivity against high-energy rays in space, and smaller efficiency degradation by heat than Si solar cells. And also by using high-volume growth techniques their complex structures can be grown with extremely high crystalline and optoelectronic quality. [5] For further improvement of the cell efficiency, cells with more junctions are being proposed such as an InGaP/GaAs/InGaAsN/Ge four-junction structure. [6]

Projected analyses show that by the middle of 21th, the global population and economic growth will more than double the energy consumption rate. By those days, photovoltaics is expected to make big contribution, to world electricity production. Until now, the most efficient photovoltaic cells are made of the multiple III-V-semiconductor materials with bandgaps spanning the solar spectrum. These days, all the commercially available multi-junction photovoltaic cells are made of triple-junction solar cells which are made of GaInP, GaAs, and Ge layers. They usually achieve typical conversion efficiencies above 30%.

© Rahim Esfandyarpour. The author grants permission to copy, distribute and display this work in unaltered form, with attribution to the author, for noncommercial purposes only. All other rights, including commercial rights, are reserved to the author.

[1] A. Luque and S. Hegedus, eds., Handbook of Photovoltaic Science and Engineering (Wiley, 2003).

[2] W. Shockley and H. J. Queisser, "Detailed Balance Limit of Efficiency of p-n Junction Solar Cells," J. Appl. Phys 3, 510 (1961).

[3] M. A. Green et al., "Solar Cell Efficiency Tables (Version 39)," Prog. Photovoltaics: Res. Appl. 20, 12 (2012).

[4] D. C. Law et al., "Future Technology Pathways of Terrestrial III-V Multijunction Solar Cells For Concentrator Photovoltaic Systems," Solar Energy Mat. Solar Cells 94, 1314 (2010).

[5] M. Yamaguchi et al., "Multi-Junction III-V Solar Cells: Current Status and Future Potential," Solar Energy 79, 78 (2005).

[6] Y. Ohshita et al., "Novel Material For Super High Efficiency Multi-Junction Solar Cells," J. Crystal Growth 318, 328 (2011).