|

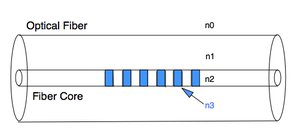

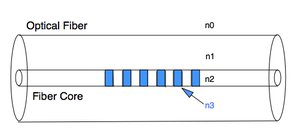

| Fig. 1: Fiber Bragg Grating Sensor. Refractive index changes allows for multi-point sensing. |

The oil industry is constantly making measurements under extreme temperatures, pressures, and cost constraints. In-well conditions typically reach 20 kpsi and 185 degrees Centigrade. [1] Electronic sensors are slowly being taken over by optical sensors, which perform well under these extreme conditions.

Because of advances in the telecommunication industry, optical sensing technology has allowed for unique monitoring methods in the oil industry. [2] Fiber optic sensors allow for well measurements even in environments deemed catastrophic for electronic systems, such as high-temperature, and high-pressure regions. [3,4] Industry is tending to use Fiber Bragg Gratings (FBGs) to monitor reservoir pressure and temperature for a variety of reasons, namely, they are very stable sensors at high temperature for long time periods, electrically passive, and can be used for multi-parameter sensing. [2]

Fiber Bragg Gratings are periodic perturbations that are encoded on a fiber optic core through a photo-inscription process. [5,6]. The perturbations allow for multi-point sensing, meaning measurements of temperature and pressure gradients can be taken. This works through measuring a the resonance shift of the Fiber Bragg Grating. [6] Fiber Bragg Gratings are extremely robust; a case study has shown an over 75% 5-year survival probability for these systems. [3] The first permanent fiber optic monitoring system was deployed in March of 1999 in Bakersfield, CA in the Kern River. The gauge that was installed was still operational a few years after deployment, with the same initial level of accuracy and resolution. [2] The first in-well monitoring system was installed by BP in April of 2000 to measure temperature and pressure. The sensor provided a pressure and temperature reading every 2.7 seconds, which lead to a megabyte of data received per day, and the data received allowed engineers to determine damage areas before serious problems occurred. [2] In October 2000, Shell installed the first optical flowmeter in the Gulf of Mexico. This flowmeter measured flow rate, water fraction, pressure, and temperature as far down as 21,000 ft. [2] Novel Bragg Gratings, and Fiber-Optic Fluid Interface Sensors are currently being developed to produce higher resolution and higher pressure sensitivity in-well. [1,7]

The success of optics in the telecommunications community over the past few decades has led to a movement in the oil industry to use fiber optics to make precision measurements. Fiber optics offer advantages over electronics in oil measurements because they can survive harsh conditions, can accurately measure many parameters, and offer permanent measurement solutions.

© 2011 Ken Ferguson. The author grants permission to copy, distribute and display this work in unaltered form, with attribution to the author, for noncommercial purposes only. All other rights, including commercial rights, are reserved to the author.

[1] R. J. Schroeder et al., "High Pressure and Temperature Sensing for the Oil Industry Using Fiber Bragg Gratings Written onto Side Hole Single Mode Fiber," Proc. SPIE 3746, 72 (1999).

[2] T.K Kragas, B. A. Williams and G. A. Myers, "The Optic Oil Field: Deployment and Application of Permanent In-Well Fiber Optic Sensing Systems for Production and Reservoir Monitoring," Soc. Petrol. Eng. 71529-MS, 30 Sep 01.

[3] S. J. C. H. M van Gisbergen and A. A. H. Vandeweijer, "Reliability Analysis of Permanent Downhole Monitoring Systems," Soc. Petrol. Eng. 57057-PA, 1 Mar 01.

[4] A. D. Kersey, "Optical Fiber Sensors for Permanent Downwell Monitoring Applications in the Oil and Gas Industry," IEICE Trans. Electron. E83-C, 400 (2000).

[5] K.O. Hill and G. Meltz. "Fiber Bragg Grating Technology Fundamentals and Overview," J. Lightwave Technol. 15, 1263 (1997).

[6] A. D. Kersey et al., "Fiber Grating Sensors," J. Lightwave Technol. 15, 1442 (1997).

[7] J. D. Weiss, " A Novel Fiber-Optic Fluid Interface Sensor," Sensors Mag., 1 May08.