Scanning electron microscopy with spin analysis (SEMPA) has created new opportunities to study the orientation and structure of magnetic domains, domain walls and magnetic singularities in materials. All of these structures are extremely complex and a best studied through direct observation.

SEMPA is a refinement to the well established scanning electron microscopes or SEM. The SEM has long been used to map the surface of materials at resolutions better than the diffraction limit of light. An SEM probes a surface with a highly focused beam of high energy electrons (<10 keV). When the highly energetic electrons hits the surface they inelastically scatter off the valence electrons in the material. Each interaction between the incident electron and a valence electron excites the valence electron and slightly reduces the energy of the primary electron. Both the incident electron and the valence electron go on to collide with other valence electrons, creating a cascade of excited valence electrons know as secondary electrons. Some of these secondary electrons propagate back to the surface where they can escape into the vacuum. The number of secondary electrons that escape is highly dependent on the topography of the surface.

As is demonstrated in figure 1 the volume of excited secondaries remains constant; however, in regions with greater surface curvature more of the excited volume is close to the surface and therefore more secondaries are able to escape. By collecting the secondary electrons generated and plotting the intensity as a function of probe position one can make a reliable map of the surface topography.

|

|

An SEM maps the topography of a sample but does not probe the magnetic properties of a sample. However, the secondary electrons ejected from a sample maintain their polarization.[1] Secondary electrons in a magnetic material are polarized antiparallel to the magnetization vector of the domain they originate from. By measuring the average spin polarization of the emitted secondary electrons the polarization of the material is revealed. Polarization can be calculated from the ratio of the spin differential to the total number of spins.

N↑ is the number of electrons with spin-up and N↓ is the number of electrons with spin down.

Secondary electrons excited from the valence band maintain their polarization after escaping the surface; however, to get an accurate measurement of the magnetization of domains in the sample the secondary electrons must maintain their polarization until they reach the spin analyzer. To maintain coherent polarization the apparatus must be shielded from stray magnetic fields and the sample surface must be clean and free from impurities that may cause spin-flip scattering. As a result measurements must take place in UHV with an ambient pressure of less than 10-9 Torr. [3] In addition, to ensure a clean surfaces, samples must be prepared and/or cleaned in situ using a sputter ion gun and an Augar electron spectrometer for characterization of the cleaned sample.

|

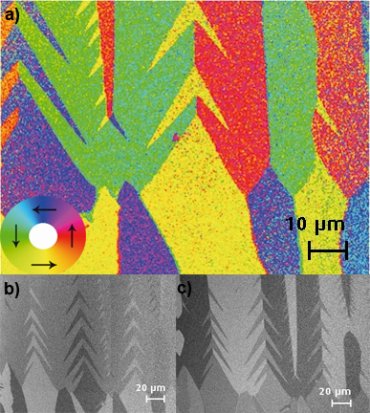

| Fig. 5: a)Map of the angle of the in-plane magnetization of Fe. Map is derived from a combination of the map Mx in figure (b) and the map of My in figure (c). The color wheel gives the relationship between color and direction.[11] |

After samples are prepared, a focused beam of primary electrons is used to probe the sample. The beam can be characterized by it's energy, current and diameter on the sample surface. Each parameter must be optimized to assure the best signal to noise and resolution in the final image. Secondary electron yield is highly dependent on incident beam energy. Lower energy beams excite many more secondaries, but very low energy beams can be deflected by the extraction field used to bring ejected secondaries to the spin analyzer. In practice the energy of the primary electrons must be at least 10 KeV.[3] The probe current and diameter are related. Increasing the probe current increases the area on the sample that will be excited by the probe. Better resolution demands smaller probe diameters, which limits the magnitude of the current. Smaller probes with higher resolution require low probe currents. Low probe currents are more susceptible to quantum noise. As a result scans with low probe currents require longer dwell times to increase the signal to noise ration, which therefore increases the amount of time required to scan a sample. An upper limit for the time for a scan is set by drift and deterioration of the sample. All these factors place a practical limit on the expected resolution of a SEMPA system at 10 nm.[4] SEMPA resolutions are quickly approaching that limit, to date the best resolution has been reported to be 20 nm by Matsuyama and Koike.[5]

The polarization of secondary electrons that escape from the sample is dependent on the magnetization of the domain it came from in the sample, but if the sample is a 3d ferromagnet it also exhibits a strong dependence on the secondary electron energy.[1][6][7]

As show in Figure 3 the polarization of Ni is artificially enhanced at lower energies. The the bulk magnetization of the domains in the material match the polarization of higher energy secondary electrons, therefore a minimum cutoff of 10 eV is applied to the electrons that are spin analyzed.[2][8]

The origin of the low energy enhancement to the polarization has not been fully explained, however one plausible explanation argues the enhancement at low energies is caused by selective scattering of minority spin electrons, which further exacerbates the spin differential to make the majority spins even more dominant. Selective scattering occurs, in 3d ferromagnets, where the valence band in filled with spins predominantly oriented in the same direction (spin up in this example). Inelastic scattering only occurs between electrons of opposite spin. From Pauli's exclusion principle Coulomb interactions between electrons with identical spin will be canceled by exchange.[9] It follows that the minority spin electrons will have a shorter inelastic mean free path and are therefore less likely to escape from the sample. This asymmetry in the inelastic mean free path decreases with increasing electron energies.

A hemispherical energy analyzer is used to eliminate low energy electrons and secondary electrons with energy greater than 10 eV are transported to a spin analyzer. Mott detectors are the most commonly used spin analyzers, however low-energy electron diffraction (LEED) analyzers, absorbed current analyzers and low-energy diffuse scattering (LEDS) analyzers have also been used. A Mott detector exploits the spin-orbit coupling of the electrons to convert spin differences into measurable spatial differences. Electrons are accelerated and scattered off a thin film of a material with a large atomic number, usually gold. The interaction of the spin of the electrons with the gold atoms causes different spins to scatter in different directions. The spin-orbit interaction is sensitive to electrons whose spin is parallel to the plane of the foil. For example, if the gold foil were oriented in the xy-plane, electrons with Sx↑ would be scattered to the right, electrons with Sx↓ would be scattered to the left, electrons with Sy↑ would be scattered up and electrons with Sy↓ would be scattered down. The scattered electrons detected by a group of four electron detectors placed symmetrically about the incident beam.

A single analyzer can measure the two polarization components simultaneously. To measure all three components, a second analyzer is necessary. The incident electrons beam is split to send half of the electrons to each of the two analyzers. The analyzers measure two independent components and one common component which can be used to calibrate the analyzers with respect to each other. The magnetization of magnetic domains within the sample can then be determine by calculating the polarization from equation (1) Topological information can be concurrently recorded as a normal SEM image by mapping the sum of all the electrons collected.

Once the polarization of the secondary electrons is calculated an image of the magnetic domains can be created by mapping different polarization directions to different colors. Figures 4 and 5 are just some examples of the type of images an SEMPA can capture.

Figure 4 is an ultrathin Fe sample epitaxially grown the (100) surface of Cu. The images clearly demonstrates one of the great strengths of the SEMPA technique: the ability to separate the topographical signal from the magnetic signal. The topography is evident in the total intensity map, as well as the individual spin intensity maps. However, the polarization map shows no evidence of the sample topography. The topography and magnetization have been separately measured.

A second example of what the SEMPA is capable of is shown in Figure 5. It maps the domains of a Fe whisker and was captured by the Danish company Omicron NanoTechnology GmbH with their commercial SEMPA. With a resolution of about 10 nm it represents the state of the art in SEMPA detectors at the limit of spatial resolution.

These examples are meant to be illustrative, not exhaustive, and highlight some of the benefits of the SEMPA technique. In addition to the high resolution and the separation of the magnetization and the surface topography, other benefits of the SEMPA system include the ability to measure many types of samples from bulk to thin films, and scan over large areas. Drawback of the SEMPA system include a predicted resolution threshold of 10 nm, required UHV conditions for measurement and sample preparation, and long scan times necessary to reduce noise created by low yields of secondary electrons and low detector efficiencies. Despite these drawbacks the SEMPA systems is well suited to studying magnetic domain at very high resolutions, and will continue to play an important role in magnetic imaging.

© 2007 J. Bert. The author grants permission to copy, distribute and display this work in unaltered form, with attribution to the author, for noncommercial purposes only. All other rights, including commercial rights, are reserved to the author.

[1] J. Unguris, D. Pierce, A. Galejs, and R. Celotta, Phys. Rev. Lett. 49, 72 (1982).

[2] R. Allenspach, IBM Journal of research and development 44, 553 (2000).

[3] M. Scheinfein, J. Unguris, M. Kelley, D. Pierce, and R. Celotta, Rev. Sci. Inst. 61, 2501 (1990).

[4] E. Dahlberg and R. Proksch, J. of Mag. Mag. Mat. 200, 720 (1999).

[5] H. Matsuyama and K. Koike, J. Electron Microsc. 43, 157 (1994).

[6] E. Kisker, W. Gudat, and K. Schröder, Solid State Comm. 44, 623 (1982).

[7] H. Hopster, R. Rave, E. Kisker, G. Guntherodt, and M. Campagna, Phys. Rev. Lett. 50, 70 (1983).

[8] D. Abraham and H. Hopster, Phys. Rev. Lett. 58, 1352 (1987).

[9] X. Sun, Z. Ding, and Y. Yamauchi, Surface and Interface Analysis 38, 668 (2006).

[10] K. Koike, H. Matsuyama, and K. Hayakawa, Scanning Microsc. Intern. Suppl. 1, 241 (1987).

[11] G. Schäfer, Omicron Nanotechnology Website (2007/03/05), http://www.omicron.de